Overview

sprungmarken_marker_192

Equipment and test benches at the Center for Emission Control Karlsruhe

In the following you will find only a short overview of our methods, plants and analytics; we will be happy to give you more detailed information upon request.

Modern catalyst preparation methods

- High-Output Catalyst Synthesis Platform

- Double-Flame-Spray-Pyrolysis setup for material preparation

- Robot-controlled coating of substrates (lab-scale)

Equipment for Analysis

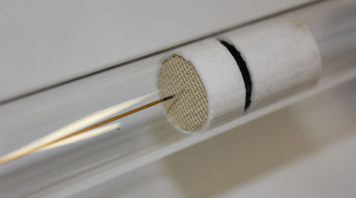

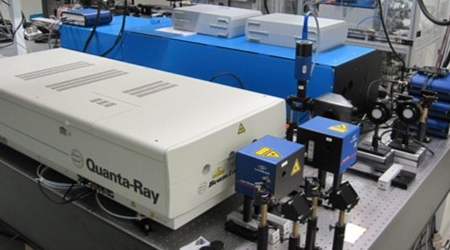

- Laser spectroscopy (LII to stody soot particles; LIF, Raman and IR to study in a time and spatially resolved manner gaseous species and tempearture profiles along catalyst coated monolith channels)

- Conventional catalyst characterization techniques: H2-TPD, NH3-TPD, O2-TPD, FTIR, BET, SEM, AAS, DR UV-VIS, XRD, TG-DTA, TG-DSC, CO/CO2-TPD/Chemisorption, XPS

- In situ DRIFT and in situ FTIR spectroscopy with gas analytics (mass spectrometry and IR-spectroscopy)

- Modern operando / in situ characterization methods: XRD, XANES, EXAFS, XRF and / or Fluorescence - XANES and EXAFS (Synchrotron radiation, XRD also conventional) combined with online FTIR, MS and GC, up to 1000°C

Additionally, available characterization techniques within KIT: HRTEM, TEM, Moessbauer spectroscopy, Elementar analysis; Hg-Porosimetry, EXAFS, XRF, XANES, Synchrotron-XRD, X-ray tomography.

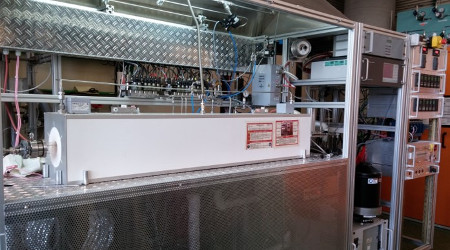

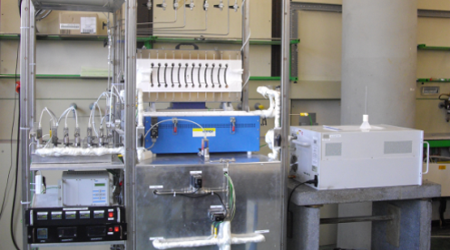

Laboratory Test Benches

- 10 Laboratory setups for catalyst tests (z.B. DOC, SCR, NSR, TWC etc.), 0.5- 70 l/min

- 2 Stainless steel reactors for a bypass-free measurement of sintered metal discs

- 2 Catalyst aging setups, 1-5 l/min, bis 1100°C

Some laboratory test benches are presented in the following in more detail:

Additional setups

- Stationary diesel engine (DI, 3 cyl., 1000 cm3, variable load, suitable for biodiesel) to produce real diesel exhaust gas and real engine soot

- Setup for catalytic partial oxidation (CPOX)

Possibility for special investigations

- Gradient-free loop recator (CSTR) for kinetic investigations

- Steady state and highly transient tests (e.g. NSR catalysts investigations with 5 s rich- and 20 s lean cycles, TWC investigations with frequency of up to 2.5 Hz)

- Isotope labeling investigations