Space- and Time-Resolved Investigation of the Gas Phase and the Active Surface/Bulk

Background: The performance of catalysts depends equally on: (1) the atomic surface structure or the structure of the molecular units, as they determine the physical and chemical and thus the catalytic properties. (2) The meso and macro scale as well as the structuring of the catalysts to account for heat and mass transfer. (3) The reactor scale, since the overall reaction rates are coupled to the flow field (laminar or turbulent) and the origin of the structured catalyst, which influence mass and heat transport. Diffusion occurs not only in the pores of the catalyst, but also in the gas/liquid flow, and the local temperature in the reactor results from an interplay of thermal conduction in the gas and solid phase, convection through the flow field, thermal radiation and chemical heat release. This illustrates the complexity of the transport processes between the molecular and reactor scale, but also offers a variety of reactor concepts and opens up many possibilities for optimizing catalyst, reactor and process design and operating conditions. Since reactor performance often changes over time due to varying operating conditions and aging, tools have been developed to monitor the reactor behavior during operation, usually realized by sensors to measure gas phase concentrations at the inlet or outlet. A new trend is the development of techniques to perform spatially resolved measurements inside the chemical reactor. So far, the catalyst design, the structure of the catalyst under technical operating conditions, the heat and mass transfer properties inside the reactor and their numerical modeling have been treated largely independently. However, they should be considered together in order to develop next generation catalysts and reactors.

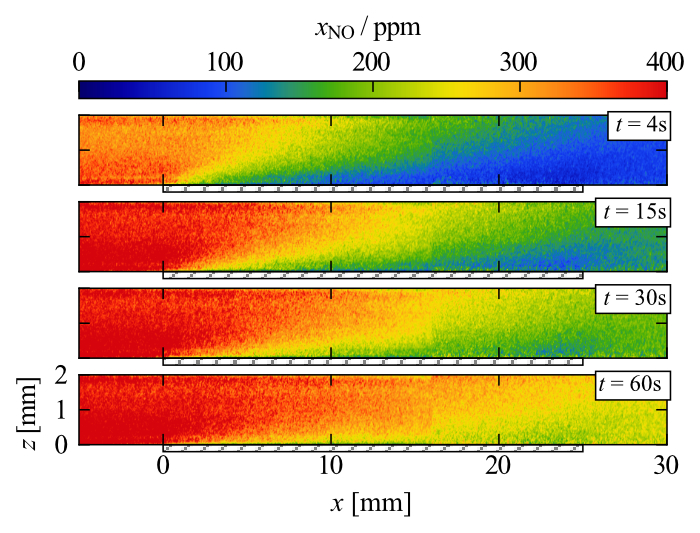

Project: This project (C4) is part of the CRC 1441 (TrackAct). The overall aim of the CRC is to track the catalytically active sites at all length and time scales with a special focus on bridging the complexity gap. To investigate structure-activity relationships, two powerful operando characterization techniques are combined in this project: planar laser-induced fluorescence (PLIF) and X-ray absorption spectroscopy (XAS). For the first time, it will be possible to directly correlate structural properties of the catalytically active component by XAS with concentration gradients within a catalytic channel reactor by PLIF. The experimental study is accompanied by time- and spatially-resolved numerical simulations of the reactive flow and catalytic conversion in the experiment. These non-invasive, experimental methods in combination with simulations allow us to gain a better understanding of realistic catalytic converters and to derive comprehensive two-dimensional structure-activity correlations. This understanding is required, for example, for multiscale modeling and optimization of catalyst activation/regeneration strategies. This approach enables the tracking of catalyst structure and its interpretation in the context of local reaction conditions and catalyst activity.

Contact: Camilo Cárdenas, Thomas Häber, Olaf Deutschmann

Collaboration:

- Prof. Dr. J.-D. Grunwaldt (KIT)

Selected publications:

S. Wan, K. Keller, P. Lott, A.B. Shirsath, S. Tischer, T. Häber, R. Suntz, O. Deutschmann, Catal. Sci. Technol. 12 (2022) 4456–4470.https://doi.org/10.1039/D2CY00572G.

S. Wan, T. Häber, P. Lott, R. Suntz, O. Deutschmann, Appl. Energ. Comb. Sci. (2023) 100229. https://doi.org/10.1016/j.jaecs.2023.100229.

K. Keller, S. Wan, M. Borchers, P. Lott, R. Suntz, O. Deutschmann, Proc. Comb. Inst. 39 (2023) 4247–4256. https://doi.org/10.1016/j.proci.2022.07.027.