Bio-based and fine chemicals

The "Catalysis for Sustainable Chemicals and Energy" group focuses on the design, preparation and characterization of solid catalysts for their use in important chemical transformations with the aim to obtain renewable transportation fuels, chemicals and monomers. Catalyst and process development for upgrading renewable feedstock (biomass and waste) into commodity chemicals is an important topic in the group. Cutting-edge research is also dedicated to understanding the catalysts and process dynamics in the hydrogenation of CO/CO2 via thermal and electrocatalytic pathways to energy dense molecules (alcohols and hydrocarbons). Green H2 production via electrocatalytic splitting of water is also investigated with advanced operando methods.

Dr. Erisa Saraci

IKFT/ITCP

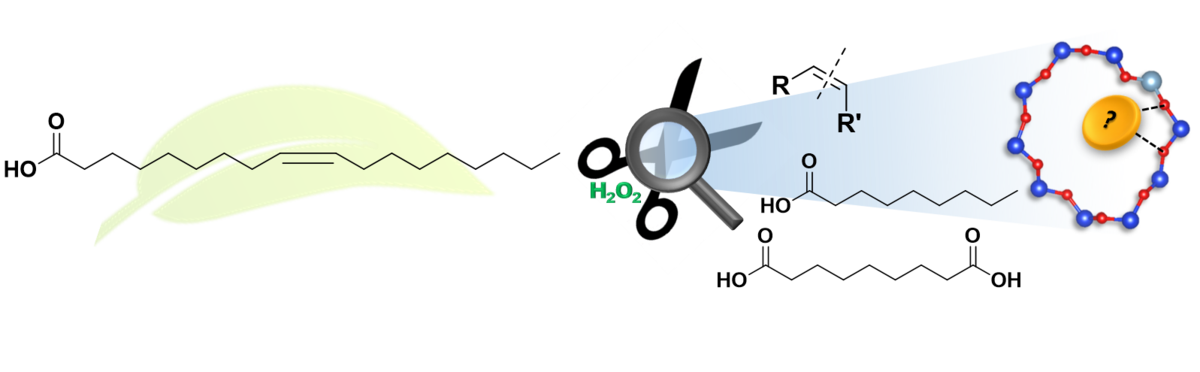

Catalytic Scissors: Oxidative Cleavage of C-C Bonds using Zeolite Catalysts

Formation and splitting of carbon-carbon bonds are one of the most essential chemical transformations, still rapidly growing in importance due to efforts to maximize the valorization potential of biomass into fine chemicals. The oxidative cleavage of C-C double bonds is a versatile chemical transformation, which allows for valorization of fatty acids, terpenes, lignin monomers or other bio-derived alkenes, yielding aldehydes and carboxylic acid with a variety of applications, suitable for a sustainable chemical industry. To come closer to this vision, we synthesize, characterize and test highly active and well-defined metal loaded zeolite catalysts, to efficiently catalyze the oxidative cleavage under mild conditions, aiming to fulfill all criteria of green chemistry.

Knowledge-based Catalyst design for Valorization of Bio-based HMF

The production of bio-based monomers is a constantly growing field in industry and academia. The synthesis of 2,5-furandicarboxylic acid (FDCA) from 5-(hydroxymethyl)furfural (HMF) is particularly interesting due to the high quantity of possible bio-based feedstocks for HMF production, like cellulose or inulin. The state-of-the-art heterogeneous catalysts for this oxidation process are based on noble metals. However, the use of biomass for the production of FDCA is still a challenge due to its complex nature. To decrease costs and increase the sustainability of FDCA production, all stages of its production have to be optimized with minimal intermediate purification steps and biomass waste, e.g. chicory roots, should be used. To accomplish this, we study the influence of by-products in bio-based solutions on the catalysts and optimize the catalytic system accordingly. We aim to develop an efficient process for FDCA production by improving the reaction conditions and process design.

Doctoral researcher: Maya Ludwig

Selective oxidation of lower olefins (propylene, isobutene)

↵

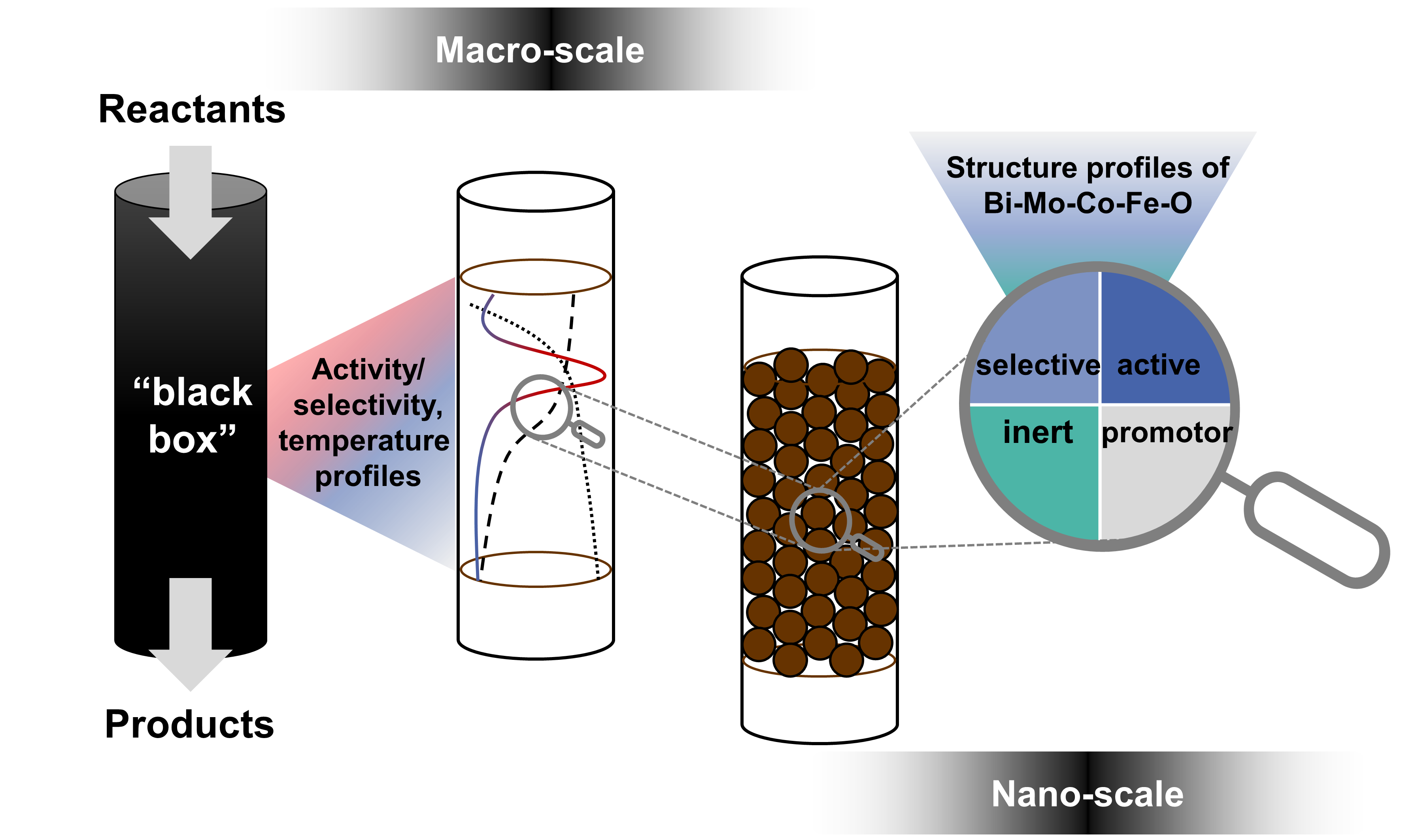

Selective oxidation processes are very important reactions in chemical industry for the production of myriad intermediates. The oxidation of propylene to acrolein as well as isobutene to methacrolein are prominent examples for such industrially-relevant selective oxidation reactions. Acrolein is further on used in different fields e.g. for the production of acrylic acid, an important polymer building block. Today, complex mixed metal oxide catalysts based on bismuth molybdates are used in the oxidation process to ideally achieve a high olefin conversion combined with a high acrolein/methacrolein selectivity.

We extensively studied the basic system of bismuth molybdates (Bi-Mo-O) and could reveal a structure activity/selectivity relationship by combining different characterization methods like X-ray diffraction (XRD), X-ray absorption spectroscopy (XAS) and Raman spectroscopy. Additionally, we extended our studies to multicomponent systems (Bi-Mo-Co-Fe-O), which represent the next step on the way from fundamental studies to real reactor ensembles. These systems consist of numerous metal oxide phases and are therefore highly complex and dynamic.

All the steps in catalyst research - namely catalyst preparation, characterization and testing - are performed within our group. The catalysts are typically prepared by flame spray pyrolysis and hydrothermal synthesis and the catalytic performance is determined in a self-build setup. For characterization, we typically use Raman spectroscopy, (synchrotron) XRD and multi-edge XAS. Selected samples are studied by in situ/operando spectroscopy to gain more insights into those systems and therefore to deepen our knowledge. By the combination of preparation, characterization and testing, we are able to rationally design and improve our systems based on the previously obtained results.

Postdoctoral researcher: Linda Klag

Available positions for students

Related publications (selection)

L. Klag, T. L. Sheppard and J.-D. Grunwaldt, ChemCatChem 2023, 15, e202201276.

P. Sprenger, W. Kleist, J.-D. Grunwaldt, ACS Catal. 2017, 7, 5628-5642.

Available positions for students

| Topic | Title | Type | Supervisor |

|---|---|---|---|

| Catalytic Scissors: Oxidative Cleavage of C-C Bonds using Zeolite Catalysts | tbd | tbd | Dr. Erisa Saraci |

| Knowledge-based Catalyst design for Valorization of Bio-based HMF | tbd | Bachelor/ Master Thesis | Maya Ludwig |

| Selective oxidation of lower olefins over mixed metal oxide catalysts | tbd | tbd | Dr. Linda Klag |